Heat Stress in Poultry - What can you do?

Heat stress in poultry - What can you do?

Eleven of Planet Earth's hottest years ever recorded have been in the last 20 years. This year the highest UK temperature ever was recorded at Cambridge - 38.7°C and the trend indicates records will be broken again and again in coming years.

Estimates vary, however it is widely assumed that each adult bird produces 10 - 20 watts of heat. On a hot day the roof of a poultry house can rise to 60°C due to the combined effects of the sun on the outside and rising heat from the poultry on the inside. If the body heat of a bird rises from 41°C (normal) to 45°C the bird will die.

Heat stress in poultry (and all other livestock production) is set to become a more frequent and an even more severe problem than it is today. Although it is a serious stock welfare and financial issue to livestock producers, it is also an issue with effects that can be minimized with preventative measures.

Where does the heat stress come from?

Apart from external heat sources the poultry produce a good deal of heat themselves as a result of metabolism - body maintenance, growth and egg production all produce heat which under normal weather conditions the heat is lost through :-

- Radiation - heat is lost from the body of the bird by radiation provided the surrounding surfaces are at a lower temperature than the bird. Conversely hot roofs and walls will radiate heat towards the birds.

- Convection - heat radiated from the bird will naturally rise towards he ceiling of the shed - where an outlet for the heat must be provided. Ventilation will assist this provided the airflow is high enough to break down the boundary layer of still air around the bird's body.

- Conduction - If the bird is in physical contact with a surface at a lower temperature than it's body, heat will transfer to the cooler object.

- External sources - Heat and humidity caused by the ambient weather conditions outside the poultry shed.

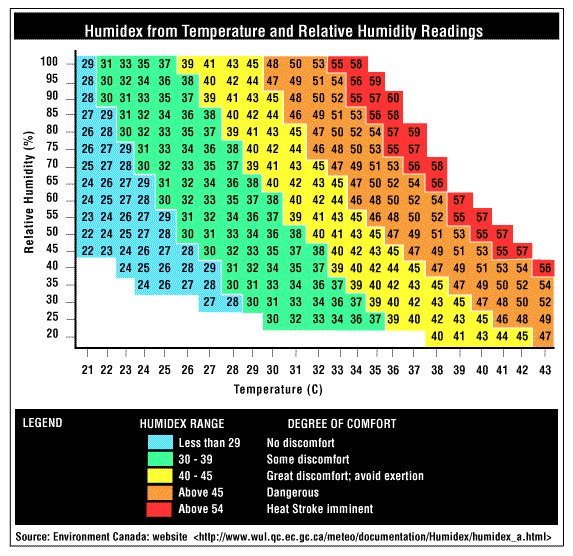

As well as sources of heat it is important to remember that heat stress results from a combination of temperature and humidity. The heat stress charts always pitch temperature on one scale against humidity on the other. For a given ambient temperature, the level of discomfort to the birds will be greater on high humidity days than if the humidity was lower.

What are the signs of heat stress in poultry?

- Birds will pant at up to 230 times a minute in order to drive off heat in the form of water vapour - hence the need for plenty of cool drinking water for re-hydration. If the conditions are highly humid the panting of the bird is ineffective resulting in a very rapid increase in stress levels.

- Interior of a typical poultry shed

- Raised wings in order to expose the featherless underwing area from which body heat (carried to the skin surface by blood vessels) may radiate.

- Pale combs/wattles.

- Lethargy.

Other consequences of heat stress in poultry.

Unless measures are taken producers will see:-

- Reduced growth rates in younger birds unable to react to rapid changes in temperature and humidity.

- Poultry discomfort chart by temperature and humidity

- Reduced egg production in more mature birds.

- Darkening of the skin colour as more blood is diverted to the surface to combat the body heat rise.

- Increased mortality in all birds but especially in the younger birds.

Measures to reduce heat stress in poultry

- Make sure birds have cool, clean water.

- Add electrolytes to water. Electrolytes help to balance the birds' own electrolytes, plus they will drink more water.

- Provide protection against direct sunshine and ensure the poultry house's exterior structure is insulated and heat reflecting rather than heat absorbing

- Reduce overcrowding and other forms of stress such as the presence of children, dogs, noise etc.

- Provide adequate ventilation to remove the rising heat created by the flock.

Importance of good ventilation

Natural ventilation is not adequate in extreme circumstances. When high temperature is combined with high humidity all animals will naturally work to regulate their own body temperatures by measures such as sweating, panting, moving apart, reduction of food intake and activity etc.

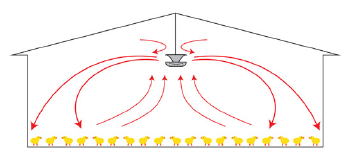

It is important under extreme conditions to turn over the whole air volume of the shed regularly and also recirculate air within the shed when internal air distribution is poor.

Remebering that heat stress in poultry is in part a factor of humidity, it is important to realise that humidity levels will be higher inside the poultry shed than outside. This is because of the littering of the stock and their sweating. Each bird delivers both heat and moisture load to the inside air. Although you can not change the humidity outside of the shed, with sufficient ventilation you can ensure that the effect of humidity on the heat stress level is no more than the outside ambient level.

Main ventilation fans can be placed either:-

- In a side wall preferably a North-Facing wall to push fresh air into the building - hot air would in this case exit the building through louvered vents in the Apex or opposite end of the building.

- In the Apex of the building to draw hot air out - fresh air would then enter through louvres in the walls (preferably North-Facing).

Internal view of Louvered Main Ventilation Fans

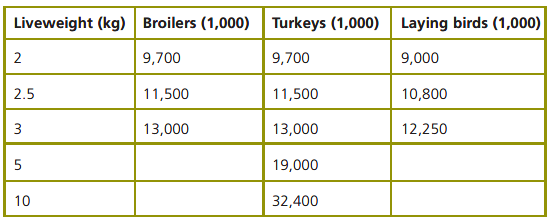

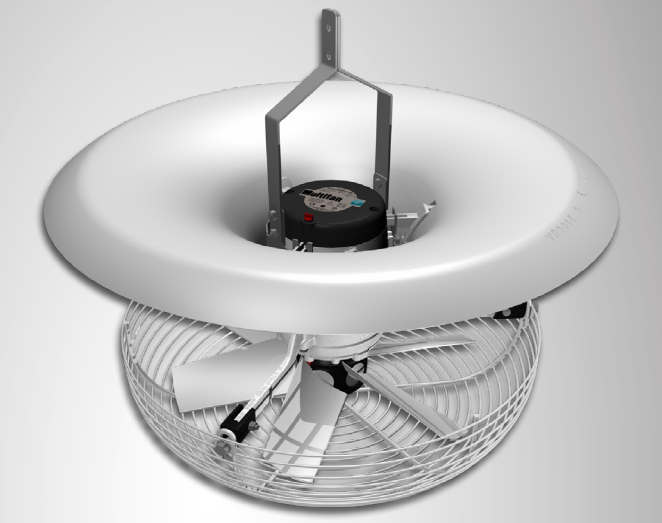

Puravent's main recirculation ventilation fans are available in 3-blade or 5-blade versions, with or without inlet cones and in a wide variety of diameters (915mm to 140mm). We also offer panel fans range in diameter from 200mm to 920mm and in power from 60W to 1.8kW. They are also available in single phase (230v) or 3-phase (440v). All have IE2 or IE3 energy efficient motors.

Puravent's Internal recirculation fans should be placed strategically around the shed so that fresh air does not short-circuit directly to the hot air outlets leaving discreet areas such as corners of rooms with no air turnover. These panel fans range in diameter from 200mm to 920mm ad in power from 60W to 1.8kW. They are also available in single phase (230v) or 3-phase (440v). This range covers air flows from 650m3/h through to 25,500m3/h.

Another method of minimising short-circuiting from inlet-fan to building-exhaust (thereby ensuring all the birds receive the benefit of the ventilation), is to create turbulence by the introduction of V- Flow fans. These ensure that air passing down the poultry house is driven out to the sides of the building as well as passing down the length of it.

Prevention of heat stress in poultry, is something that we know about and can help with. To view the full range of fans visit our website www.puravent.co.uk or call us on 01729 824108 to discuss your specific requirements.