A guide to Industrial Air Cleaners

Industrial Air Cleaners - Background

Fugitive dust is a problem in various industries and even in ones that do not have dusty processes. Industrial air cleaners are most often used to treat fugitive dust problems. From the outset we have to make a distinction. ThisFugitive dust is a problem in various industries and even in ones that do not have dusty processes. Industrial air cleaners are most often used to treat fugitive dust problems. From the outset we have to make a distinction.

This surface might not be so dusty if an industrial air cleaner had been used

This guide is not about 'process dust' and it's control, it is about 'fugitive dust, i.e. dust that is in the wider air space and is either a health risk issue of a nuisance by settling on equipment, work surfaces, raw materials or finished products. Process dust, by contrast, is dust that is captured at source with a local extract ventilation system (LEV) and carried via ducting to dust collection systems prior to discharge, usually to the outside environment.

As industrial processes become more advanced so the equipment used to control them becomes more sophisticated and sensitive. We have found that computer based process controllers, optical sensors, micro switches, and other sensitive electro mechanisms are all acutely sensitive to dust contamination.

Fugitive dust can have many sources; External Sources

- Roads

- Quarrying

- Mining

- Agriculture

- Land fill operations

- Open air grit, or sand blasting

- Neighbouring dusty industries

Internal Sources

- Processes

- Raw materials

- Materials handling operations

- Disintegration of building materials (e.g. floor, roofing materials, walls)

- Packaging

- Fabrication activity

- Cleaning activity

Production

| Marketing

|

Overheads

| Health and Safety

|

The objective to industrial air cleaners will be slightly different from one application to the next depending on the issues and regulations applicable in their sector, however in most cases the objective for airborne dust reduction will be to reduce dust to below 50µg/m3, which is in line with the European directives for outside air based on 10 ?m particles and less (PM10). In most cases this can be achieved and with it come the benefits of having much cleaner air.

Industrial Air Cleaners - Approach

At Puravent we have been supplying commercial air cleaners since we started trading in 2003 and are well placed to provide suitable air cleaners for industrial applications. Fugitive dust problems are typically solved using ceiling or roof hung air cleaners which have their own fan and filter system, and which operate by continuously processing the buildings' air through the filters. The type and number of industrial air cleaner will not only depend on the size of the room in which the air cleaner(s) are to be used, but also what the type of dust is and what the level of contamination is.

We generally supply either industrial air cleaners based on bag and panel filters which are an ideal solution for smaller applications and those with lower dust contaminant levels, or larger industrial air cleaners based on filters packed with fine polypropylene fibres, which have huge dust holding capacity. Although the latter type are more expensive per machine, for larger applications and particularly those with higher concentrations of fugitive dust, their dust holding capacity and typically larger areas covered per unit, make them cost-effective.

There is always a cost to buying, installing and running an array of industrial air cleaners, and that cost must be weighed against the costs of doing nothing. The costs of doing nothing divide into those which are easy to measure, e.g. product wastage and cleaning costs, and those which are less tangible e.g. staff health risks and poor company image. Once you have both the costs of doing nothing and the costs associated with the air cleaners, you can work out how quickly the industrial air cleaner installation will 'pay back' the investment.

In order to control fugitive dust in a building we typically work on the basis of ensuring that the industrial air cleaners will provide enough flow to achieve a certain amount of 'room' air changes in an hour. The design air change rate and choice of machines will vary from one application to another, and will depend on;

- Room size - length (m) x width (m) x height (m)

- Type of dust, and its concentration

- Level of occupancy and 'traffic' in the building

- Machinery and processes in the building

- Shape of the room - it might be a simple rectangle which would suggest that each of multiple units would be the same, or if it is a less regular shape say with a number of different size rectangular shapes then this usually suggests using different size units.

- Air ingress rates and sources

- Ventilation rates

- Heating air and cooling air flows

As with other types of installed air cleaner, locating the industrial air cleaners in the room will depend on the room size and shape but generally where there are multiple units they should be equidistant with half spacing to from the machine to the walls. A single unit should be as close to the centre of the room as reasonably possible.

Although these are our regular range of air cleaners we can supply other types and brands if required. Just ask us.

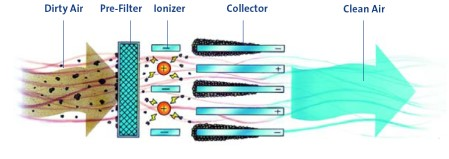

Industrial Air Cleaner Operating Principles

Industrial air cleaners that based on standard panel and bag filters, like the Record AC1 and Record AC2 have a relatively predictable performance on filtration efficiency, and will generally process less air as the filter becomes caked in dust. This increase in pressure drop over the filters and resultant loss of flow is what gives rise to the need to change filters and the relatively high running costs.

The filters in the larger E series industrial air cleaners by Zehnder are designed to have far higher dust holding capacity. Although they don't have such predictable filtration efficiency performance, the efficiency is high enough for the vast majority of industrial applications. The relatively low filter change frequency helps to ensure that the running costs are as low as they can be particularly for larger applications. For applications where there is a particular efficiency requirement, a prefilter box can be added to the E series industrial air cleaners.

The main filter in these units are Flimmer filters, which are a based on a mass of electrostatically charged polypropylene fibres. They rely initially on electrostatic charge to attract dust particles to the fibres, however as the filter gets more laden with dust the filter effect changes from electrostatic to interception and impingement with the fibres. Because the fibres are arranged in parallel to one another although there is a mass of fibres the air resistance, even when dirt laden is remarkably low. It is for this reason that the Flimmer filters in the E Series industrial air cleaners have such a large dust holding capacity; up to 10 times that of the equivilant duty bag filter and have much lower running costs during the filters' life.

Arrangement Of Industrial Air Cleaners

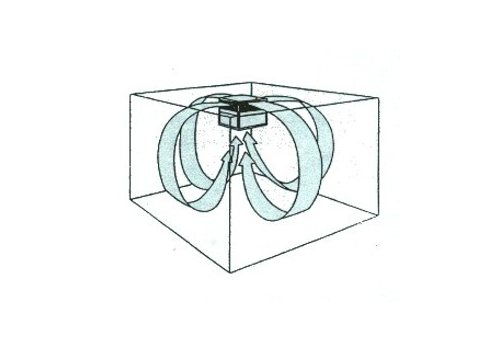

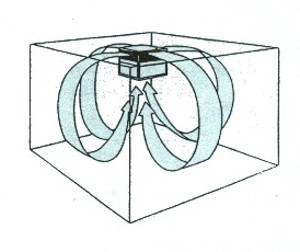

Air flow pattern to typical industrial air cleaner

Usually industrial air cleaners are supported on chains form the roof structure, however in some cases this is not suitable and units are wall mounted or floor mounted. In most cases the units are arranged for air entry through the lower face and discharged from the sides, but they can be arranged to extract from any direction to suit the application.

It is also worth considering that air cleaners not only clean the air that they move, but also contribute to its thermal destratification, by inducing air movement that lifts cooler air and replaces it with warmer air that has risen to the roof line. This means heating costs are reduced and separate destratification fans will be required in fewer numbers, if at all.

If you need help solving an indoor dust problem or have questions about industrial air cleaners, ask us - 0845 688 0112

Guidelines and Regulations Concerning site dust (click title to activate link)

HSE webpage - Grain dust in non agricultural workplaces may affect your health

HSE webpage - Wood working - wood dust

HSE leaflet - Stone Dust and You

HSE webpage - Grain dust in non agricultural workplaces may affect your health

HSE webpage - Control of Exposure to Silica Dust in Small Potteries

HSE webpage - SAFE to BREATHE - Dust and fume control in the rubber industry