UVC HVAC applications - Knowhow for treating COV-2

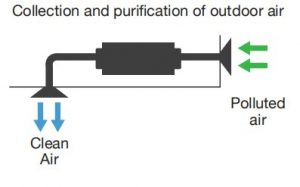

The topical background to UVC HVAC systems is that with the onset of cooler weather the widely recommended option of supplying 100 % fresh air ventilation in order to make buildings safe from the COV-2 threat is looking increasingly expensive. That fresh air is going to need a huge amount of heat to maintain some semblance of comfort for the occupants. Air purification using UVC is another option to make those buildings safe and it does not require heating masses of fresh air.

Easy UVC air purification - the mobile units.

The applications for UVC air purification fall into a number of groups. There are many applications in buildings that do not have any form of mechanical ventilation, which in the scheme of things are older buildings, and smaller buildings, possibly containing offices and meeting rooms of various types. This is the easiest fix. For these type of applications we generally supply stand alone air purifiers. Our preferred range for this is the Sodeca UPM products which have been outlined here and which we offer here.

UVC HVAC in void spaces

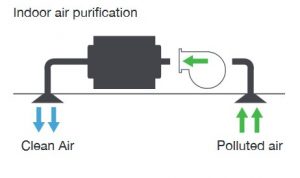

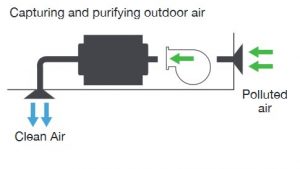

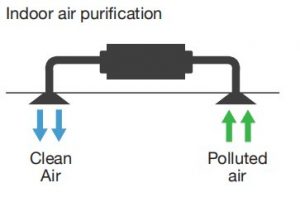

In the absence of a centralised ventilation system complete with air handling units, some buildings have ceiling void space which lends itself to a localised ventilation system either to bring in air from outside or to recirculate air from the room with air purification before return to the room. For this type of application there are a number of UVC air purification systems that we offer.

If there is an existing ventilation system above the ceiling then it will already have a fan in the duct to either bring in air from outside or to recirculate the air from the room, and the only addition need is a UVC air purification chamber to be added into the ducting.

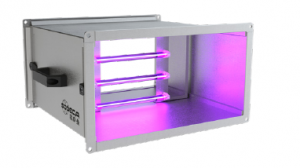

The Sodeca range offers three solutions for this type of application covering rectangular ducts and rounds ducts.

UVC HVAC - getting airflow and the dose right

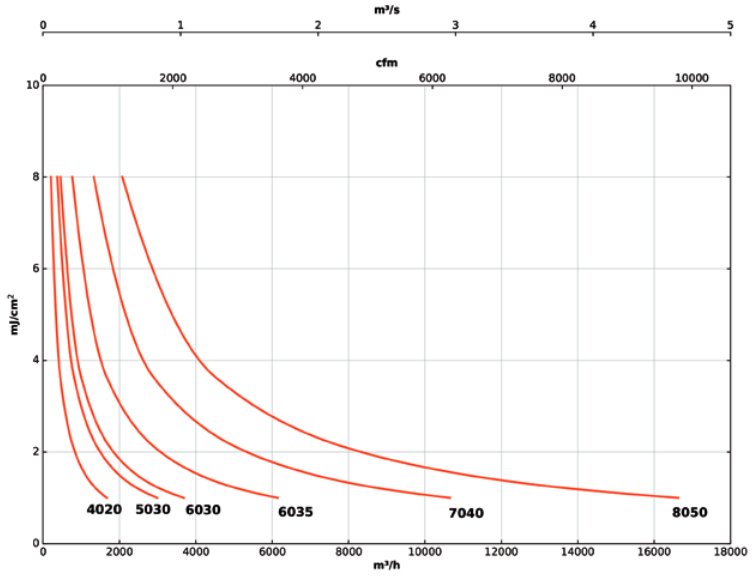

Matching the most suitable unit to the application is not simply about matching the duct size. Airflow though the duct also has a bearing on the efficiency. The clue to this is in the UVC dose charts which highlight the diminishing UVC dose as the airflow increases.

The key to working this out is to be able to measure the air velocity though the duct. If you know the velocity and you know the duct size, you can work out the duct face area and thus the volume air flow, in your chosen units (cfm, m3/hr or m3/s). Once you know the flow you can choose a unit that will provide a UVC dose that makes sense for your application.

The UVC scale on these graphs is mJ/cm2. In very rough terms, accepting that the percentile performance depends on a number of other factors not least the actual micro organism that you are targeting, you can use a rule of thumb that for COV-2, 1 would equate to 95%, 2 to 98%, 3 to 99.5%, 4 to 99.9%. 5 and above and you are near to 100% as matters.

If the chosen model has an inlet and outlet spigot that is larger than the existing duct, it is not a problem because duct transformers for the standard duct sizes are cheap and available.

UVC HVAC - getting air change rate right

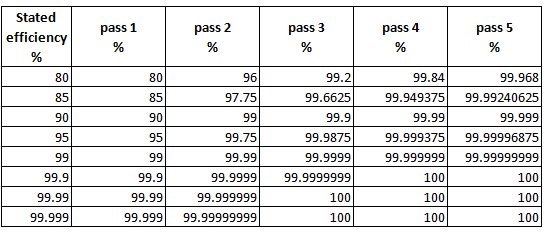

If your ventilation system is recirculating air then the efficiency of the UVC against your particular target microorganism is less important because every time the air passes through the UVC chamber the same efficiency is repeated. In other words it does not take long for say 95% repeated to accumulate to as near to 100% as matters.

It means that air change rate is every bit as important as the headline efficiency of the UVC chamber at deactivating the target organism. It does not take Einstein to work out that if you have a 95% efficient UVC chamber that is achieving 10 air changes on a room then assuming no further creation viable COV-2 viral particles then in round terms, in 6 minutes the system will have done an air change and reduced rooms viral load by 95% and in 12 minutes, (2 air changes) by 99.75%. This is why at Puravent we do not bang on about efficiency in isolation because on its own percentage efficiency is both misleading and meaningless. Room size, airflow, and air change rate are a fundamental part of the equation.

The greater the air change rate, the quicker the system treats an emission of viable viral particles. The converse way to look at it is to understand that an air purifier which is 100% efficient is almost useless if it only produces 1 air change per hour (ac/hr).

If you have, for example, an office where one out of the ten staff is COVID-19 infectious then knowing that in an hour the air will be 100% purified is not exactly a comforting thought. With the infection source continuously adding viral particles to the airspace, the ventilation system or air purifier will simply not keep up.

Air change rate is critical. Understand this and work on a rate of at least 10 ac/hr in order to actively suppress viral load in occupied rooms. Many buildings that do have mechanical ventilation will have ventilation rates that are far less than this, and for these types of application consider supplementing the existing mechanical ventilation with in room air purification.

UVC HVAC - application in fan coil units (FCUs)

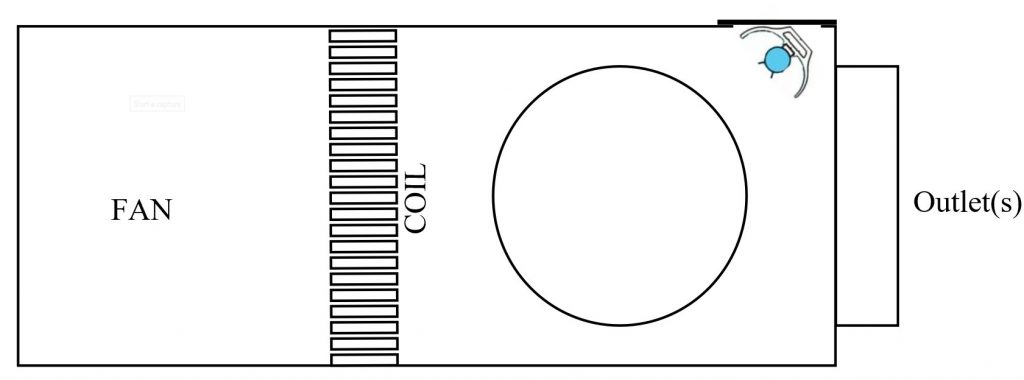

For some buildings, particularly those containing larger office environments, there are numerous fan coil units (FCUs) that process, clean, cool and heat the air. Typically a large portion of the air being processed is recirculated and because of this it is a good idea to use UVC to purify the air before return to the fan coil unit or on the supply side of the fan coil unit. The problem though is that with these system space is often very tight. Typically there are two options we can investigate.

Use Sodeca range of duct connectable UVC chambers - see section above. The problem with this is that often on fan coil units the supply flow from the fan coil unit splits at the outlet plenum into a number of round or rectangular ducts which means that a single fan coil unit might need 2, 3, 4 or perhaps even more duct connectable UVC chambers.

The other option is to see if there is enough space in the outlet plenum to fit UVC surface disinfection units. This option does take a bit of work and it involves converting the outlet plenum into a UVC chamber by cutting a suitably sized 'letterbox' slot into the top of the plenum to accommodate the longest UVC object purifier unit that can fit in without obstructing airflow to the outlet ducts. An oversize cover plate is made to cover the slot and the UVC object purifier fitting is mounted to the cover plate before fitting to the fan coil unit.

Unlike using the duct connectable UVC chambers where we know the UVC dose and can have a reasonable idea about efficiency, this conversion of the outlet plenum is a less precise science. We offer this type of equipment on the basis that for a very difficult application it is as much UVC dose as you can reasonably expect to deliver to the supply air as it passes through the plenum. These are invariably recirculation systems and even if the efficiency against COV-2 is only say 90 or 95% on 1st pass, it has a huge benefit, when you consider the effect of multiple passes.

UVC HVAC - applications with larger ducts

Whilst the duct section UVC air purifiers are a relatively easy way to install UVC HVACs' smaller ducted applications, when it comes to larger airflows we use in-duct UVC. The in-duct UVC system we supply is called Sanuvox Biowall.

The beauty of Biowall is the modeling of the performance specific to the application. This means that when we know the air flow and the duct size these parameters and others including a Biowall size selection can be put into a modeling program and the performance of deactivation of the selected micro-organism can be accurately calculated for the first pass and subsequent passes.

If you are interested in discovering more about the Biowall system these blogs will help;

- In-Duct UV-C Air Purification – A Beginners Guide

- HEPA filter & UVC? Or a choice of one or the other?

For help on UVC HVAC applications, call us.