Destratification Fans and The Heat Strata Problem

The fact that hot air rises and cool air sinks is well understood elementary physics. Because it tends to happen in commercial and industrial space heated buildings, it is not only a problem for the comfort of staff, but also a needless additional heating cost. Destratification fans solve this problem easily and cost effectively.

Thermal Stratification

The fact that hot air rises and cool air sinks is well understood elementary physics. Because it tends to happen in commercial and industrial space heated buildings, it is not only a problem for the comfort of staff, but also a needless additional heating cost. Destratification fans solve this problem easily and cost effectively.

The problem is that the warmer you need a room to be the more heat energy you need to put in. In low ceiling rooms such as domestic rooms this is ok because you experience the warmth relatively close to the ceiling, however, in high ceiling rooms such as is typical in factories, warehouses and retail buildings there can be a large variation in temperature between the air immediately under the ceiling and the air at about 1-2 m from the floor.

Temperature variation of between 2-3°C per 5m of height are possible, and with some ceiling heights of up to 30m the difference in temperature can be over 12°C.

This causes a problem because in order to heat the occupied level to say 17°C, the air towards the top may end up being well over 20°C. It is this additional temperature in the higher strata of the room which represents wasted energy and cost.

Even in warmer times of the year, night-time temperatures in the building can take a very long time to lift to a comfortable level. In this situation the air close to the ceiling picks up the sun’s heat quite early in the day, however with little effect reaching the shop floor level. This means that the use of heating can often start earlier in the season and end much later than would be the case if the air was thermally destratified.

With some industrial buildings condensation is a problem which is made considerably worse because of stratified air. Condensation will form where warm air meets cold surfaces. The greater the differential between the surface temperature and the air temperature, the more condensation that results. The undersides of industrial roofs, particularly those that are poorly insulated, is often where drips of condensation will form, which can cause damage to the building as well as equipment, and product it contains. Reducing this temperature differential between at ceiling level by destratifying the air will reduce this problem.

The Cost Of Stratified Air

- Operating Costs. It is well recognised that by destratifying the temperature in a room, that significant heating cost savings can be made. Most experts agree that provided that destratification is effective, the savings can be expected to be between 20% and 50%. Investment in destratification invariably pays for itself in savings very rapidly. The other way of looking at it is that for as long as you don’t have destratification fans in place, somewhere between 20 and 50% of your heating cost is being wasted. It is often suggested that 10% cost can be saved in a 4m ceiling, and the savings increase by 1.5% for each meter in ceiling height.

- Capital Costs. The cost impact is not only running costs of heaters; it is sometimes also the capital cost of oversized heaters. This is particularly the case where there is a heat creating process in the room from which heat rises to the ceiling rather than be distributed. If it is not warm enough, the layman’s assumption might be that heaters are needed, whereas the sensible first stage is to fit destratification fans and then assess if heaters are needed, and if so what capacity they need to be.

Destratification Fan Solutions

The instinctive assumption is that destratification fans are the answer. In fact they are only one of a number of possibilities. We always recommend that the 1st stage is to consider the heating source in the room. Straight convection heating is of course the worst offender for creating stratified heat, but in many cases heat is delivered by installed space heaters that are not positioned or set up to counter stratification. Where heating is by wall mounted units and the room width is almost within the air throw range of the heaters, they can be positioned and set to ensure that a circular airflow pattern in the room is created this in most cases will be perfectly sufficient to prevent thermal stratification.

In larger rooms where the central area of the room is beyond the reach of the wall mounted heaters ceiling hung heater will often be installed.If choosing ceiling mounted heaters it is worth considering desertification in the characteristic of the various options available.

Heaters that gather air from the upper horizontal plane and discharge the air vertically downwards can be viewed as destratification fans that provide heat rather than just heaters. Along this line, the Frico SWT water fed fan heaters are useful, as are the vertical type Thermolier steam fed fan heaters.

Some industrial and retail building have airborne dust issues to deal with as well as the more usual issues of heating in winter. Here again an alternative to the traditional destratification fan crops up. Both conventional ceiling mounted air cleaners and high capacity fan filter units constantly process air through filter media, to catch all the airborne dust that would otherwise settle and collect on working areas, product packaging, raw materials or the pre packed product itself. These air cleaners move air in a room in similar pattern to a destratification fan and can help prevent thermal stratification. As an aside, it is often the case that the installation of poorly set up space heaters makes dust nuisance suddenly become apparent.

The lesson in this is that rather than looking at destratification as a problem unrelated to other issues in the building, to look a bit wider to the other issues that have a bearing on the thermal stratification. It may well be that clever product choice can solve a number of issues including thermal stratification.

Destratification Fans Type

Destratification fans are designed to induce air movement which ensures that air is mixed to produce a uniform temperature, but there are two ways to do this;

- Preventative. Some fans have very low air flow relative to the area they are capable of treating and these are generally those that are designed to operate continuously of certainly whilst the heating system is on. They operate continuously to prevent stratification. Preventative type destratification fans such as the Airius range typically have a downward pointing discharge snout which directs a column of air from the fan to the floor ensuring a complete height air circulation loop. Helecentrifugal fans are also typically used in preventative way although the circulation is in the reverse direction.

- Reactive. Other destratification fans have much higher airflows relative to the area they treat and they tend to be operated by differential thermostat control. This means that they operate only when a preset temperature difference between floor and ceiling has been exceeded and they then move quite high airflows to rectify the temperature difference and stop once the temperature difference has been reduced below a preset level. Although if properly specified, reactive fans can push air right down to the floor they do so based on a far greater flow of air.

To consider each of these types in turn;

Round Cased Destratification Fan

Blandovent destratification fan

Airius Destratification Fan

Within this range are a number of different brands of fan however, the principle range is by Airius who make a number of models of destratification fan, each being suitable for installation within a defined height range.

The largest model, the 100, being suitable for rooms with ceiling heights from 19 – 31m. Having established the correct model the next stage is to select the fan density of the installation. The density of the fan deployment will depend on both the actual height of the fan installation and type of building in which the fans are to be located.

Generally the higher a particular model is mounted, there more of them you will need. Also buildings with higher occupation densities will require a higher density of destratification fans than those with lower levels of occupation. For example, an Airius model 25 can have a range of deployment densities from a 65m2 per unit for a 8m ceiling height in a busy retail type application to 120m2 per unit for a ceiling height in a warehouse type building.

Over the years we have sold several Airius units. Although they can be painted to any

Airius destratification fan set into suspended ceiling

Airius Suspended Ceiling Kit

Airius destratification fans have an added bonus in that they can be mounted in a suspend ceiling. We don’t know of any other type that can. The addition of a ceiling kit means that the unit can blend into the space of a standard ceiling square. The ceiling kit comprises of ceiling plate that allows inlet air through pattern the radial slots into the fan and a central orifice through which the discharge outlet of the fan housing fits. There is also a cover that goes over the top of the fan which ensures that the recirculated air is directed from the radial slots into the fan inlet. With the ceiling kit the fan is supported by the ceiling plate rather than its’ hanger.

Over the years we have sold several Airius units. Although they can be painted to any RAL colour code for an additional cost, some customers choose to undertake this themselves. One theme that comes out of this range is that people like the units’ aesthetics. Sometimes the unit, although more expensive than standard destratification fans, is chosen because it is the best fit the appearance of the room. A customer who was converting an old church building into a trendy nightclub was delighted that they looked ‘well cool’.

Of the destratification fans we supply perhaps the ones from Airius are the most credible and without doubt the most effective for higher roofed buildings, where their narrow column of discharged air actually reaches the floor. This video demonstrates this point superbly.

They have been tested and reported on by BSRIA and have numerous documented case studies about their effectiveness and quick return on investment. The payback on installations of Airius fans is typically between 12 and 24 months. The various models in the range can be either controlled via a simple on/off control or they can be connected to speed controller. However the fans are controlled, the advice is to keep them running at least while the heating is on, and ideally also when the heating is not on.

Helicentrifugal Destratification Fans

The helicentrifugal destratification fan range only has two models, King K75 and King K100, however between them they cover rooms with ceiling heights up to 18m, which makes them a contender for the vast majority of applications. The big difference with these fans is that, they work in reverse compared to other destratification fans. Instead of a column of warmer air descending from the fan, air is lifted directly to the fan and discharged horizontally from the fan. This creates an air circulation pattern in the room which achieves the same objective as other destratification fans, but with better overall air mixing throughout the room and less drafts. The absence of down draft means that the helicentrifugal destratification fans can afford to move more air and thus cover greater areas than other brands

It means that they are the preferred choice where there are general heat circulation problems (not just stratified heat) and in rooms where there are higher levels of staffing that may otherwise be exposed to the discomfort of down draft from a normal fan. These fans are very quiet and cover a considerably larger area than other destatification fans.

In some applications the availability of single phase power is slightly limited by the scale of the building and the locations of existing cable runs, and here it is useful that the King units can be supplied as 3 phase units.

Helcentrifugal destratification fan

The reverse air flow pattern of helecentrifugal destratification fan

Helicentrifugal Destratification Fans – Case Study – Horticultural Sector

Helecentrifugal destratification fans installed in greenhouse

Probably the very best application for destratification using helecentrifugal fans is in green houses, and particularly those with automatic roof vents. In this application the practical benefits are as follows;

- Destratification of heated air in winter

- Quick internal distribution of solar gain on the inside surface of glass in the mornings

- Excellent cooling effect in warmer months, particularly when the roof vents are open (fresh air pulled in) and doors are open (warm air pushed out)

- Constant air movement is excellent for reducing plant losses due to rot and disease, particularly if plants are in pots on elevated mesh platforms

A recent customer installed eight K100 fans in a large commercial garden centre/nursery greenhouse operation and the economic benefits included;

- Significantly reduced heating costs

- Increased customer footfall in greenhouse in summer due to more comfortable temperature

- Plant losses due to scorching and drying out eliminated

- Plant losses due to rot and disease virtually eradicated

Standard Destratification Fans

Standard units are available from a number of manufacturers. The brand that we supply is the Frico range which includes a couple of models, one, the ICF20 with protection class IPX0, and the other, the ICF55, with protection class IPX5, which means that it has some protection against water spray. The ICF55 is a useful model for applications where there is likely to be periodic exposure to water based processes and spray.

Although the standard destratification fans usually cost far less per unit than more modern fans it is often a misleading comparison because the area that they cover is typically far less so that more are needed in order to achieve the same destratification effect. However if the room that they are to be used in is of relatively small size in relation to its height, like many smaller industrial units are then, it is often far cheaper to use 1 or 2 standard destratification fans than to use 1 of the more costly ones.

The Frico ICF units have a wide variety of control options, including;

-

Twin thermostatic speed controller

-

IPX0 5 step speed controller (IPX0 or IP54)

-

Variable speed controller

Generally any one controller can control a number of ICF units

The units are mounted directly onto the ceiling or roof structure, with a drop shaft vertically down from the mounting to the motor and impeller. The standard units come with a shaft length that give a fan height of 545mm and blade diameter of 1422mm, however there are other options that are available including;

-

200mm rotor shaft giving an overall fan height of 395mm

-

750mm rotor shaft giving an overall fan height of 914mm

-

914mmØ fan blade set

- 1218mmØ fan blade set

We supply the Frico ICF destratification fans rather than other standard type destratification fans because the availability several control options, blade diameters and mounting heights, provide a much wider range of application possibilities than would otherwise be the case.

Square Cased Destratification Fans

Square cased fans are a cost-effective installation because they are generally made using standard fans, casings and louvers. Although more effective than standard destratification fans they are not as effective as modern round cased units. In applications with modest ceiling heights they can be a good solution and because some have adjustable louvers, they can be set to direct airflow into areas which may otherwise be difficult to reach. It is interesting to note that in order to effectively destratify the air in an application, an array of square cased fans will have to move much more air than an equivalent array of round cased fans. This therefore means that they are likely to be more noisy and be more costly to operate.

Comparison Of Destratification Fans

When considering the various options for destratification fans it is vital to understand the relationship between the ceiling height and the resultant floor area that a particular model can be effective over. The following comparison graph possibly has too much detail to see clearly on the webpage, however you can click on it to open a .pdf file of the same image.

Destratification Fans Comparison Checklist;

- Area coverage per machine not only has effect on the number of machines, it also by default drives the number and method of control, and the cost of installation. Needless to say the fewer units you deploy the lower the installation cost.

- Noise levels. Although destratification fans are generally all pretty quiet, there are differences, and if the units are to be used in say office, educational or retail environments noise may well be a critical factor in your decision.

- Power consumption. It is possible to compare models on a watts per m2 basis and thus to workout the comparative running costs for the different systems.

- Control density. i.e how many units can be controlled from a single controller. The answer to this will affect the capital cost and installation costs.

- Down draft issues

- Airflow. Some destratification fans have quite large air flows compared to others that theoretically cover the same area. The thinking here is that some fans are designed to destratify stratified air, whilst others are designed to prevent stratification happening. Maintaining the destratified air takes a lot less air flow and power, than rectify stratified air.

- Lateral thermal mixing need and system effectiveness

- Fan mounting. Remember the fans that can hang on chains are very easy to adjust for height and Airius have an advantage in that they can be angled to point where required

- Cost. Of course.

Destratification Fan Installation and Planning

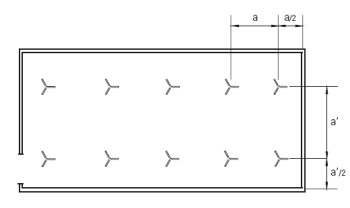

When planning an installation of your chosen fans, it is worth working out the ideal layout for your fans given the size of your room. Generally using the maximum rated floor coverage per fan for the planned mounting height, as a guide for sourcing the correct number of fans, the next stage is to work out the actual floor area per fan given the area you have in the room (divide the room area by the fan number). To get the spacing between fans, use square root of the area per fan.

With the fan spacing you should then be able to sketch up a layout along the lines of the one shown.

The tricky bit is that the ceiling structure seldom allows an installation plan to be follows exactly, but you should aim to get the locations as close as possible to the spacing on your plan. Generally once actual positions are decided, the units are installed by somebody suitably skilled and equipped, and generally electrical connection work and wiring should be done by a qualified electrician.

Control Of Destratification Fan Systems

Although it is possible to run destratification fans from complex thermostat systems, where they come on if there is a larger than preset temperature differential between the ceiling and floor level, it is not something we generally recommend.

The reason for this is that heating systems are generally operated on thermostats, which control the heat input and to also have a fan system that is control by thermostat, can lead to the combined system ‘hunting’. The result is that both the heating system and the destratification fans cycle on and off with an irritating frequency as they both try to compensate for the action of the other.

It is far better to let the heating thermostat control the overall heat input into the room and leave the destratification fans on for at least whilst the heating is on (whether blowing heat or not). Better still leave the destratification fans on all the time, because this way even when the heating is off, you will get the benefits of destratification beyond just the winter months.

Control using a fan speed controller is recommended as it enables users to switch the fan on when the heating is on or when needed in the summer, and also to adjust the fan speed to suit the application. But bare in mind that not all destrat fans are suitable for running from a speed contoller.

Summary

The range of destratification fans that we supply is pieced together to enable us to be able to offer credible and sensible solutions to the vast majority of the thermal destratification applications that we encounter. There are numerous choices when it comes to space heating and thermal destratification. If you need help to navigate through the options call us on 0845 688 0112