Looking for industrial dehumidifiers? Click here to browse a range containing products from the likes of Aerial, DehuTech, EcorPro and Ebac.

VRF300 desiccant dryer industrial dehumidifier

Commercial/Industrial Dehumidifier or Desiccant Dryer?

In order to start to appreciate the capacities of desiccant dryers, it helps to first understand the limitations of refrigerant based industrial dehumidifiers. We know that the performance of conventional dehumidifiers depends largely on the temperature of the ambient air and its relative humidity.

The higher the ambient humidity and temperature, the greater the extraction rate for a particular dehumidifier. From this it follows that the dehumidifier is working at its' most efficient when air is 100% RH and temperature is as high as it reasonably can be, say 35°C. Therefore it is also true that dehumidifiers become less effective and less efficient as humidity and temperature decrease.

At lower temperatures and humidity they become both ineffective and inefficient. Desiccant dryers, using a completely different mechanism for reducing humidity operate at much higher efficiencies at lower temperature that compressor based dehumidifiers.

The role of Desiccant Dryers

Material processing

Powder silos

Pneumatic conveying

Mechanised handling

Production processes (e.g. pressing, moulding, coating)

VRF1000 desiccant dryer

Prevention of Mould

Healthcare

Cargo protection

Flood & water damage

Brewing

Archives

Seed and grain

Cotton and FabricFoodstuffs

Product Drying

Cured meat drying

Smoked fish drying

Production of cultures based additives incl. yeast

Confectionery coating processes

Pharmaceutical materials handling and product finishing

Food drying pre packing e.g. herbs

Trotec TTR700 Desiccant dryer

Prevention of Condensation and Corrosion

Military storage depots

Generator storage

Pumping stations

Power distribution

Bulk metal storage

Metal component storage

Museum artefacts

Lay up of Marine vessels, aircraft and vehicles

Storage silos and tanks whilst out of use

Meat processing

Ice rinks

Plastics manufacturing

Cold stores

Silos

Water treatment

Pumping stations

Desiccant Dryers - How they work

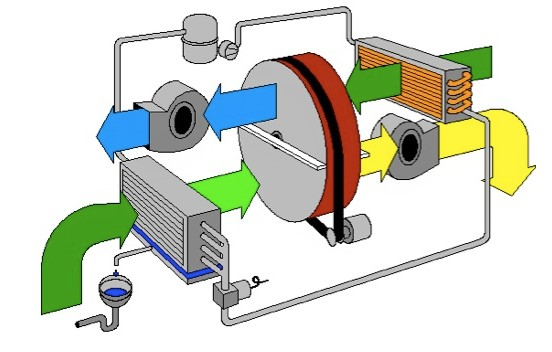

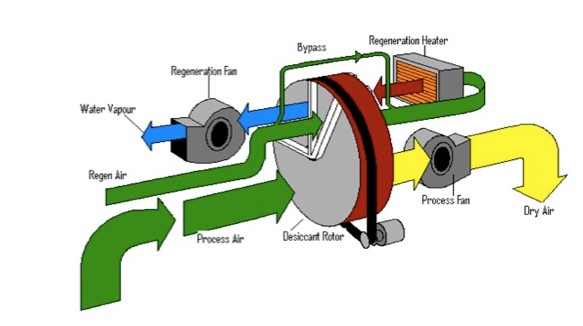

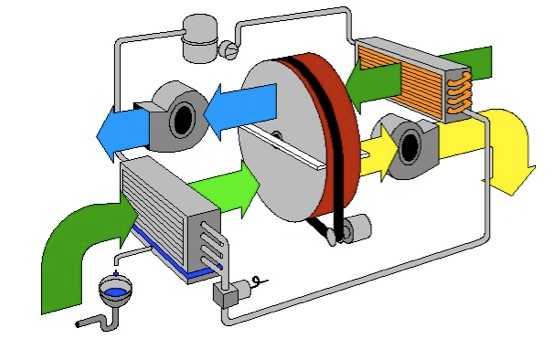

Humid process air enters the desiccant dryer and passes through a slowly rotating fluted wheel. The surface of the wheel is coated with an absorptive material, usually silica gel, so that as the air passes through the flutes on the wheel there is effective contact between the moist air and absorptive gel.

The gel absorbs moisture from the air therefore reducing its humidity. The rotating absorption wheel has during the majority of its cycle process air moving through its flutes. The rotating wheel has a smaller section of its cycle dedicated to desorption, where a reverse flow of hot air is blown through the flutes. This forces the water held by the silica gel to evaporate thus drying that section of the wheel in preparation for its cycling through the process air drying section.

The basic desiccant dryer mechanism

This desiccant drying process results in a drying process that is less temperature dependant than drying by refrigerant based mechanisms, but rather than condensate, the collected moisture from the process air is discharged as water vapour on the heated regeneration air flow. Although this describes the basic desiccant dryer mechanism, there are a number of variations to the theme which are used in different dryers depending on the requirements of the application. Desiccant dehumidifiers are ideally suited to use in cooler ambient air, or when low humidity levels are required.

The process is continuous and closely controlled with the wheel turning approximately 3-4 times per hour and the regeneration section being about 25% of the overall wheel face area.

Variants to the basic Desiccant Dryers

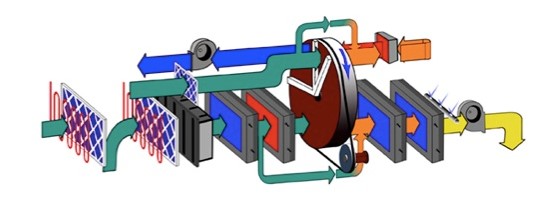

The regeneration heater is usually an electric unit but can also be a coil based running of hot water, steam or compressed refrigerant. In the case of using compressed refrigerant the setup is usually part of a compete refrigerant cycle including precooler coil and heater coil. This hybrid system is in effect a two stage unit with the higher humidity inlet being dried by the precooler coil and the more challenging drying lower down the RH scale being done by the desiccant wheel.

Desiccant dryer with DX precooler

In some applications there can be safety issues with using electric elements, for example component temperature restriction in ATEX applications. Depending on the Temperature class, elements can either be low temperature electrical or water fed coil.

VRF Special desiccant dryer

Desiccant dryer with preheater precooler, after cooler, and filter stages

Desiccant Dryers - Puravent Capabilities and range

We work very closely with the leading manufacturers of desiccant dryers, which means that as well as being able to offer standard units from stock can also offer a wide range of capabilities and features in units built to order, incorporating design specifications that are needed in your particular application. This includes but is not limited to;

- High airflow versions

- High pressure versions

- Various filter efficiencies up to HEPA and ULPA

- Coils including preheating, precooling, post heating and post cooling

- Control options, including remote switching, monitoring, humidistat, and BMS interfaces

- ATEX rated units including both dust and gas categories.

Trotec TTR5000 desiccant dryer

If you need help with a drying problem, however complex, give is a call, 0845 688 0112

Looking for commercial dehumidifiers? Click here to browse a range containing products from the likes of Aerial, DehuTech, EcorPro and Ebac.