- Heaters (37)

- Ventilation (6)

- Cooling (27)

- Dehumidifiers (7)

- Air Purifiers & Cleaners (26)

- Fans (21)

- Air Curtains (2)

Desiccant Dryers For Preventing Silo Clogging

Silo Clogging - The Desiccant Answer

The bulk materials that are stored in silos are often adversely affected by humid air, where issues can include silo clogging and agglomeration, and increased levels of corrosion to handling equipment. Within the closed environment of the silo humidity can fluctuate as the ambient temperature changes, such that a drop in ambient temperature means that the dew point of the air inside the silo is reached before that of the outside air. The resulting condensation will typically cause product caking inside the silo and associated handling equipment and corrosion. In short, silo clogging

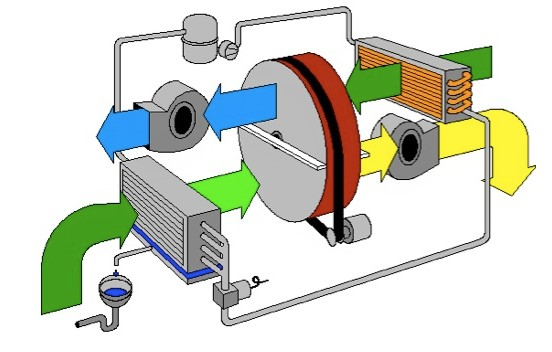

This problem is easily averted by using a desiccant dehumidifier unit to push very dry air into the silo head space, where a modest air change rate will have a profound benefit on the handling qualities of the stored product and prevent corrosion.

To reliably prevent silo clogging, we normally recommend the VFR (T) range of dehumidifiers for this application. Their higher than standard process fan pressure enables them to maintain a positive pressure in the silos head space and depending on the product being stored may even enable the supplied air to be ducted in at a level below the head space. Some times we can connect a unit to the filling line, which means that a new duct need not be fitted.

Although the desiccant dehumidifier would typically run all the time on this type of application, silo filling is the exception to the rule. Typically the desiccant dehumidifier would be switched off and isolated from the silo air during filling operations, to prevent back flow of dust air through the dryer, and then once the filling is complete, the desiccant dehumidifier can be brought on-line again to re-establish the low humidity environment inside the silo.

Even if the dry air is supplied into the head space of the silo, this is enough to effect drying of the air amongst the material at the base of the silo because water vapour moves into dry air humidity areas to reach an humidity equilibrium because of Dalton's Law.

With dry air throughout the silo interior, the granular or powder contents will be dramatically easier to handle using conventional conveyor equipment without the material 'bridging' or 'rat holing' in the silo hopper, or clogging in the pipe. Silo clogging will become a thing of the past.

Want to know more about desiccant dehumidifiers? Try our guide or have a gander at the video

Articles related to this product

-

Puravent know a thing or two about ATEX rated desiccant dryers and can offer suitably certified machines to suit your ATEX gas or dust zone application.09/07/15

-

Desiccant dryers and industrial dehumidifiers can be used in numerous applications where dry air is critical. Learn more in this Puravent guide.09/04/21